©

Sören Pinsdorf / LUH

©

Sören Pinsdorf / LUH

For high-tech industrial societies, a secure and independent energy supply is crucial. Renewable energy sources are now central in this regard because they are also available in unlimited quantities in resource-poor countries and are sustainable and climate friendly.

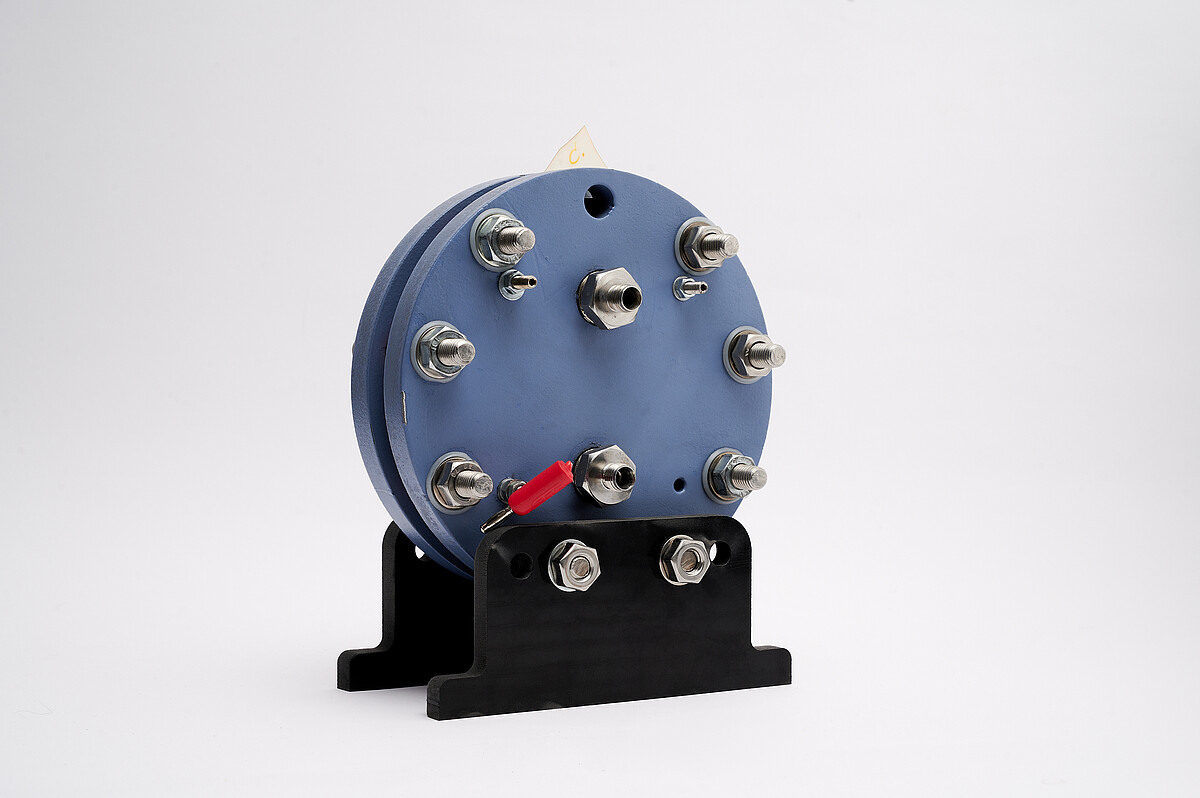

Water electrolysis plays a key role in producing so-called green hydrogen from renewable sources. It allows for the effective conversion of renewable electric energy and water into hydrogen and oxygen.

Until now, the production of hydrogen using water electrolysis has been more of a niche application and has been used in those locations where there was no access to natural gas infrastructure, where extremely cheap electrical energy was available or where very high purity requirements were in place for the product gases. Research and development work has therefore been on hold since the 1960s and 1970s. In the future, though, a significant increase in capacity will be necessary: the current hydrogen demand in Germany is 1.8 megatonnes annually (globally: 54 megatonnes/year) and will double over the next year. To enable the electrolytic production of these amounts, an increase in electrolysis performance to at least 30 gigawatts from today’s low two-digit megawatt level is necessary in Germany alone. For roughly the last 10 years, this has led to an increasing interest in the area of electrolysis producers and a growing need for research and development.

At Leibniz University Hannover, the Institute of Thermodynamics (IfT), the Institute of Electric Power Systems (IfES) and the Institute for Solar Energy Research in Hamelin (ISFH) are contributing significantly to this development, focusing on two of a total of three technically relevant electrolysis technologies. One of these is so-called polymer exchange membrane water electrolysis (PEMWE), which is conducted at temperatures around 80°C and is characterised by a very compact construction and high level of flexibility. The other is solid oxide water electrolysis (SOE). This is carried out at temperatures around 800°C, is characterised by particularly good electrical efficiency and is especially suitable for transformative routes where hydrogen is only an interim product – for example, in the production of synthetic fuels. The work at the three institutes focuses both on the optimisation of the central element of the particular technology, the so-called membrane electrode assembly and other important cell components, and on the overall system context including questions regarding system design and operations management. The common methodological element of all these projects is the combined use of modelling and simulation tools and experimental characterisation and validation.

The three institutes working on the topic of water electrolysis are part of LUH’s key research area “Energy Research” and the Energy Research Centre of Lower Saxony’s hydrogen research area. Additional information is available here:

Video: Hydrogen – tomorrow's clean energy source? (in German)

Please note that activating the video will result in the transfer of data to the respective provider. Further information can be found in our privacy policy.

Play video

Participating researcher

At the Institute of Electric Power Systems, Prof. Dr. Richard Hanke-Rauschenbach and his team are working to further develop water electrolysis, with the goal of improving the efficiency, operating lifetime and cost.

©

Julian Martitz/LUH

©

Julian Martitz/LUH

Contact person, Communications and Marketing

30167 Hannover